Metal 3D printing

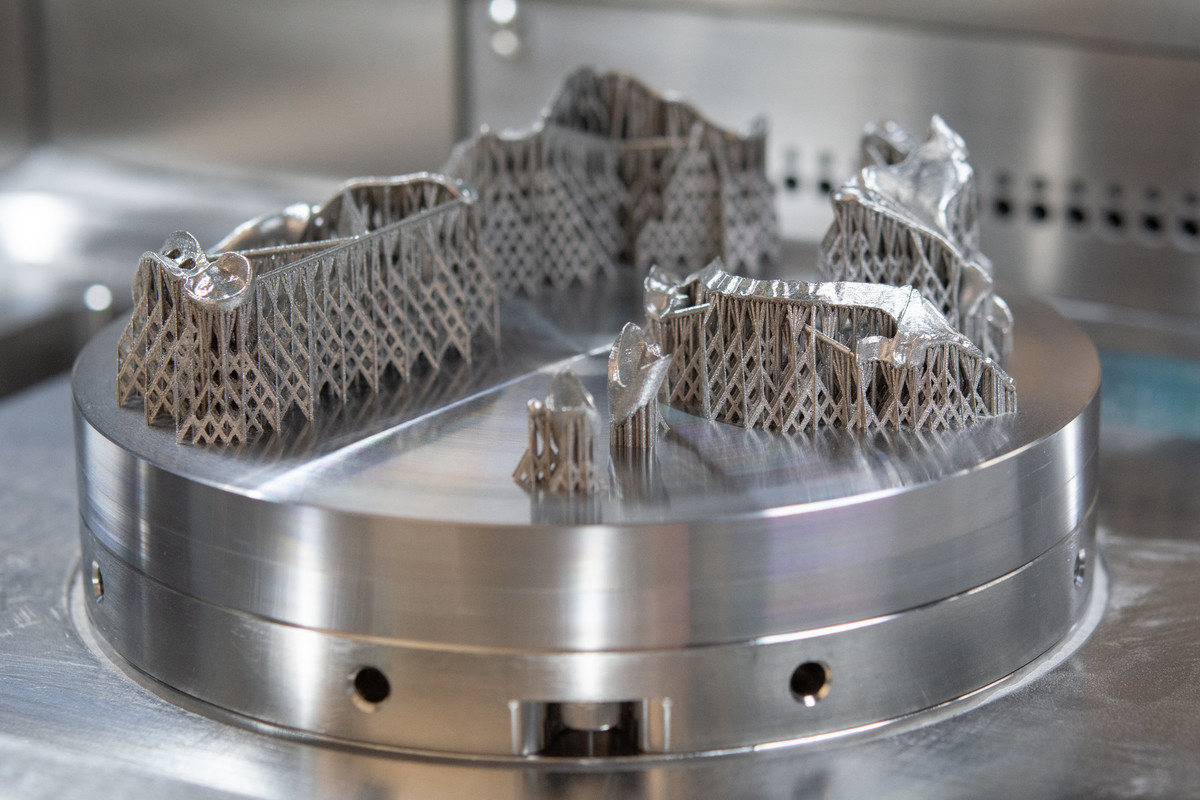

Metal printing covers a wide range of combined technologies to achieve superior results. DMLS® (Direct Metal Laser Solidification) is a proven PBF (Power bed fusion) technology for almost three decades, which is today the standard in 3D printing of metal parts. The DMLS method was primarily used for production in demanding industries such as aerospace, automotive, medical, toolmaking ... These industries require the same quality of parts as would be achieved with conventional casting processes.

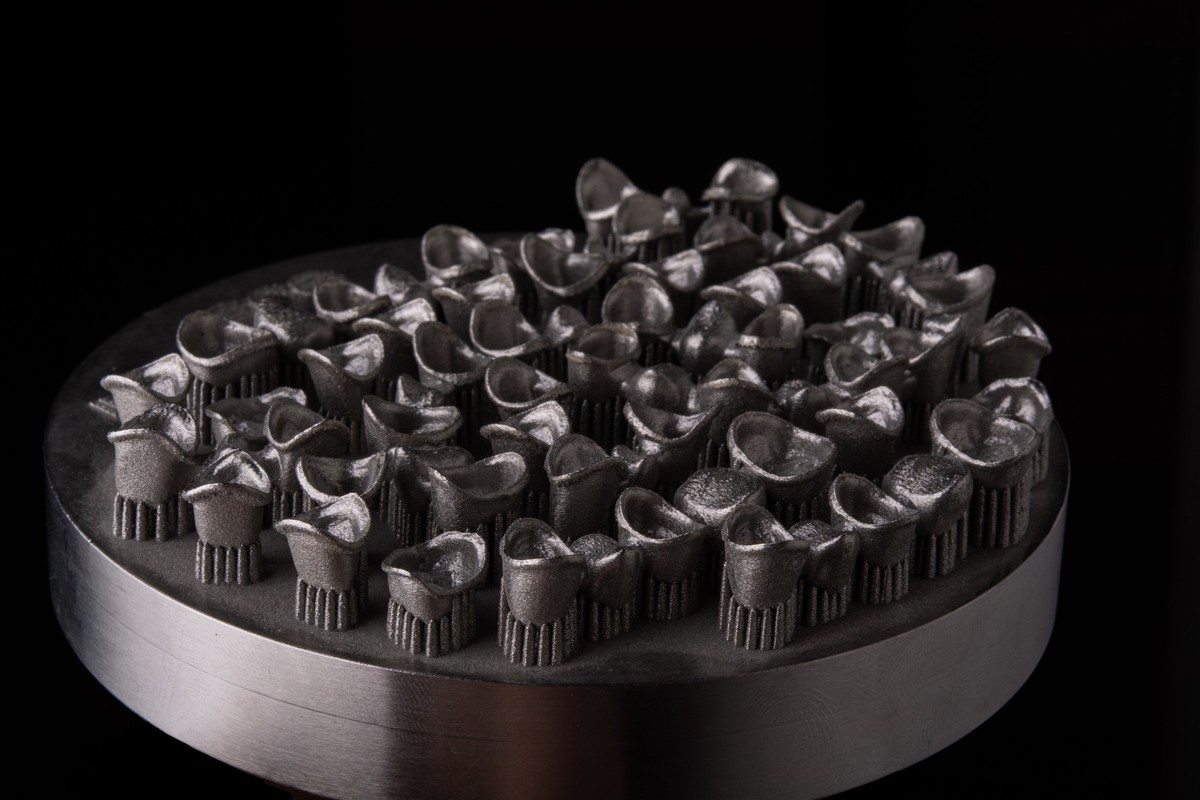

DMLS laser printing offers a new, unmatched quality in the production of metal frames. The micro-structured surface of the frames with a print resolution of up to 30 µm, ensures extremely precise constructions, without internal stresses. The extremely powerful laser provides an incomparable density of material, with excellent tensile strength. In addition, thanks to dust control technology, the quality of the components is automatically monitored and is constant.

The quality and stability of the beam and the 200-watt power of the laser fiber ensure optimal and consistent conditions for the production of high-quality components. A small laser dot with excellent resolution is ideal for making very complex and delicate parts. The EOS M 100 printer is ideal for printing dental crowns and bridges as well as other medical devices.

The main advantages of our printed constructions:

- Best material properties with excellent metal density

- Tension-free construction for careless application of ceramics

- Great fit

- Controlled and constant quality work process

Materials